Delineating a Rational Profession:

The Machine Drawings of Engineers in

Early Nineteenth-Century Britain

- Frances Robertson

_______________________________

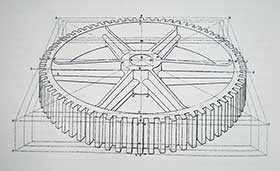

Fig. 7. Mechanical Component, 1818

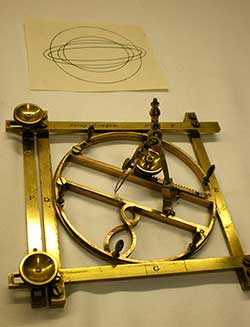

Fig. 8. J. Farey, Elliptograph, c.1812

More specialized instruments such as ellipse drawing machines, offer similar puzzles. New inventions such as the John Farey’s Elliptograph were smooth automatic mechanisms that used very familiar geometric principles. Draughtsmen were already accustomed to drawing this curve by various methods with very simple resources [20]. So why were such expensive and fiddly new instruments invented by so many people, and why were they in demand [21]? Comparing two devices for drawing ellipses from museum collections, the trammel and the elliptograph, gives more idea about the objects in use, and helps us to differentiate between them [22]. The moving circles in the elliptograph are only 10 cm across, so it drew ellipses that are no larger than 7cm in length, whereas the trammel can throw out a curve up to ten times that size, of around 70 cm. Larger curves from the trammel were used to make workshop and production drawings, as a step to making objects, whilst the images drawn by the elliptograph are small because they were intended purely as a step towards printed images. John Farey, the inventor of this particular device, developed and expanded the visual language of engineering in a distinctive manner by using machine aids deliberately, as engineering projects that served his own professional trajectory as a writer-engineer [23]. So, when employed as a draughtsman for Rees’s Cyclopaedia he captured images such as John Smeaton’s London Bridge waterwheel for the London Waterworks in pictorial perspective from a slight oblique angle, first sketching the machine on site with the help of a Wollaston-type camera lucida, using pencil. Farey’s underdrawing at this point was extremely sketchy, but he transformed his rough notation when he worked it up in ink, relying on mechanical drawing aids to create an effect of accuracy (ranging from ruler and compass, through to his own inventions, such as the elliptograph and centrolinead) [24]. He announced his pragmatic method, using machines alone, without too much calculation or observation, in his article ‘Drawing Instruments' in Brewster’s Edinburgh Encyclopaedia:

All that is required, as data for describing any ellipsis… is to sketch them in pencil on the paper, and mark, by the compasses, the four points upon each curve where its two diameters intersect it. Place the instrument [the elliptograph] upon the paper in such a position, that, by estimation of the eye, the centre of the four rulers seems to coincide with the centre of the intended ellipse [25].

Farey is quite clear here; in place of hand-eye coordination skills that were previously valued, he puts an engineered solution to the task of observational drawing, deputizing his conceptual knowledge to the machine. Although many artists had used such devices in a secretive way, Farey did not hide this aspect of his practice. Instead, he celebrated mechanical drawing aids, and shared these techniques through publication. His unvarying inked lines, laid in by machine and diamond point, were the ‘chaste' product of a self-registering technology that had no need of hand crafting skills and gained authority because they were mechanically drawn—so Farey asserts a new and opposite virtue from Adams’s embodied craft skills. Farey’s drawing machines supplanted personal body discipline, and instead asserted the ability to control and command endlessly repeatable and accurate copies.

Engineers developed various spheres of operation: in the two-dimensional world of paper where they presented ‘engineering' in texts and images, as well as in the three-dimensional world of material structures, professional combat and factory organization [26]. Machine drawing displayed new and specific professional skills that marked a clear separation from artistic and even design practice, where such aids would only be called on covertly. Inventing and using drawing machines also announced allegiances with other activities such as instrument making and the sciences of accurate measurement and making across a whole range of activities from practical technology to science. Ruling machines made diffraction gratings and fancy buttons for gentlemen; accurate division was the goal of precision screw manufacture in both industry and astronomy, while elliptical and rose-engine devices aided both the close contemplation of gear workings or the cosmic tracks of celestial bodies [27].

Fine measurements and reliable standards in both machines and in drawings were of course central to the development of metrology and standardization later in the nineteenth century [28]. But at the turn of the nineteenth century, the claim to be able reliably to execute known geometrical forms in the real world also carried weight, notably in the promotion of James Watt’s condensing steam engine that was sold on the basis of improved fuel economy. His engine helped the user to save money on fuel due to marginal improvements in performance based on theorized control of form. Superhumanly neat inscriptions on paper functioned as a promise to deliver such custom-made designed goods in the material world.

So on the one hand, machine drawing was propaganda about control, an articulation of the virtues of standardization and repeatability. Drawing machine operations were geometrical, and by feedback, their actions were applied to innovative machine forms in the real world, famously for example in Watt’s use of the pantographic principle in his parallel motion mechanism governing the upstroke of the piston in the double acting steam cylinder [29]. Designing machines and designing drawing machines went together; the planing machine devised by Roberts uses a very similar forward motion mechanism to the ruling machine that produced engraved lines. Collaborative working towards the production of images, via machines, draughtsmen, and engravers can also appear as a utopian assertion of industrial enlightenment and cooperation [30]. In the communications to the Transactions of the Society of Arts, inventor, draughtsman and engraver appeared to be equal in this self-styled forum of the useful arts where roles were interchangeable [31]

On the other, untidy side of this topic, looking at the material techniques and skills involved in the production of machine drawings, or thinking about and handling the instruments themselves, reveals some of the inconsistencies in this episode of competitive invention and prompts useful questions about the self-fashioning of engineers through apparently frivolous visual diversion. Handling and seeking out these machines can be time consuming. One has to negotiate spaces within the schedules of busy museum curators, and they in turn have to negotiate the annoying frustrations of guarding their massive dusty collections with constant funding anxieties. Their collections are perhaps not fully catalogued, and even if they are, objects still get constantly shunted around as categories or storage priorities change. But while the inertia of old objects might be a frustration, the peculiar time-zone inside the archive is also a blessing for the researcher. In writing this article, I am grateful to have had access to the collections of the National Museum of Scotland, in Edinburgh, founded as the Industrial Museum of Scotland in 1857, and specifically conceived as ‘a castle stored with the ammunition and weapons of commercial warfare.' [32] George Wilson, the first Director, valued his stores of drawing equipment. To him, all kinds of drawing instruments, from lowly pens, pencils and brushes through to untested newly invented devices were important weapons in the armoury of ‘Dynamical Industrial Art.' [33] Handling some of these machines shows just how unhandy they were. For example, amongst other items in the collection we encounter the Diagraphe by the French inventor and engraver Charles Gavard [34]. This is very fiddly to assemble, with its tiny pulleys and string-driven mechanisms, not unlike threading a sewing machine. Gavard’s machine is worthwhile examining in use, because it features in Martin Kemp’s The Science of Art (1990), but only in a somewhat frictionless way where it is used to support a narrative of a progressive science of optical enquiry. Kemp’s focus on the history of ideas, with images used to illustrate this narrative, obscures the reality of this uncomfortable operation [35]. The little supporting wheels, which supposedly give smooth drawing action in any direction, jam and jerk just like their large counterparts on the base of supermarket trolleys. No wonder, as David Napier observed, that draughtsmen would use any shift to copy drawings without having to resort to machines like this [36].

The relentless geometrical perfection of the discourses of the drawing machines in print are far from the obdurate material realities of their operations in the actual world. The conceptual development of drawing machines represents a continuation of the simple procedures of ruler and compass; that is, they repeat the technologies that engineers applied to themselves. Drawing with these tools is to execute a repeatable action, completely unlike free hand doodling. So machine drawing was a kind of teaching aid, a means of reinforcing consensus of hand-eye-brain drawing actions across a community of practice, of shaping ‘perceptions as practice.'

The first stages for apprentices when working in drawing offices, in training on the job, was to copy existing drawings, executing the same actions as one’s predecessors; in many contexts, geometrical drawing was instilled by drill methods [37]. Such rote learning, using guide tools to shape drawings, engineering production, and also junior engineers, bypassed the conscious centres of the brain and inscribed tacit knowledge directly in an example of the interactions of training, machine knowledge, human skills and practices [38]. While the use of technical representations to control subordinates at a distance is a well-understood concept, in fact drawing was also used as self-discipline, a means of controlling one’s own expression. While drawing is often conceived as the trace of an intimate autographic gesture, engineers aimed to standardise the actions of the hand on the page. The perfect actions of machine drawings objectified those personal practices, making them self-generating and also self-evident.

[20] At the most basic level, one can draw an ellipse by laying a loop of string around two pins or sticks (placed in the foci) and drawing within that loop. Other simple devices include the trammel (discussed below).

[21] In 1851, for example, the catalogue of Elliot Brothers’ instrument manufacturers gave the price of a trammel at £2-12s-6d, whilst Farey’s elliptograph cost £7-17s-6d; see J.F. Heather An Elementary Treatise on Descriptive Geometry, London: John Weale, 1851: appendix.

[22] I thank the National Museums of Scotland, Edinburgh, for access to the John Farey Elliptograph (c. 1812) T.1969.16 and George Adams Semi-elliptic trammel (c. 1775) T.1897.185.

[23] John Farey, Jr. achieved public eminence as an engineering consultant and patent agent; for example giving evidence to the Select Committee on Patent Laws in 1829. He became a member of the Institution of Civil Engineers in 1826, and towards the end of his life acted as a juror for the machinery section of the Great Exhibition of 1851. However, his later professional standing was based on the training he received by observing machinery and developing techniques of writing and draughtsmanship while working on Abraham Rees’ Cyclopaedia (1802-1819) from 1805 in collaboration with Wilson Lowry the steel engraver. See A.P. Woolrich, ‘Farey, John (1791-1851),’ Oxford Dictionary of National Biography. Ed. H. C. G. Matthew and Brian Harrison, Oxford: OUP, 2004. Online ed. Ed. Lawrence Goldman on the Oxford Dictionary of National Biography.

[24] A.P. Woolrich, ‘John Farey, Jnr., Technical Author and Draughtsman: His Contribution to Rees’ Cyclopaedia,’ Industrial Archaeology Review XX, 1998, pp. 49-67; A.P. Woolrich, A.P., ‘John Farey and the Smeaton manuscripts,’ History of Technology 10, 1985, pp. 181-216.

[25] ‘Drawing Instruments,’ Edinburgh Encyclopaedia volume X 1830, pp. 121-132 ; p. 132.

[26] John K. Brown, building on the work of writers such as Steven Lubar, notes that while Victorian engineers had several motivations for using mechanical drawings (that he characterizes as ‘instrumentalist, professionalizing, and political’), they did not own up to all of these elements. By contrast, the instrumentalist view that drawings are simply a rational vehicle for designing and manufacturing was a strategic form of self-presentation commonly adopted by engineers and historians of drafting such as Baynes and Pugh (1981). See Lubar, Steven, ‘Representation and power,’ Technology and Culture, Supplement to Volume 36, 1995: S54-S74; J.K. Brown, ‘Design Plans, Working Drawings, National Styles: Engineering Practice in Great Britain and the United States, 1775-1945,’ Technology and Culture 41 (2), 2000, pp. 195-238.

[27] Ruled lines and elegant rainbow-coloured buttons came first, diffraction gratings, following the work of Fraunhofer in the 1820s, came later; see P. Grodzinski, ‘A Ruling Engine Used by Sir John Barton—and Its Products,’ Transactions of the Newcomen Society Volume XXVI, 1947, pp. 79-88; for accurate division, see the primary sources already cited in this article, and also R.C. Brooks, ‘Towards the Perfect Screw Thread: The making of Precision Screws in the 17th-19th Centuries,’ Transactions of the Newcomen Society Volume 64, 1992, pp. 101-119, Holtzapffel 1842-84.

[28] W.J. Ashworth, ‘The calculating eye,’ British Journal for the History of Science 27, 1994, pp. 409-41; S. Schaffer, ‘Metrology, Metrication and Victorian Values’ in B. Lightman, ed., Victorian Science in Context, Chicago: University of Chicago Press, 1997, pp. 438.

[29] Marsden 2002: 117-120 In relation to the ‘problem’ of not being able to create a true straight line, noted by Kempe (1877) or Bryant and Sangwin (2008), this is a good example of how a provisional and partial solution was seen to be perfectly satisfactory in its context.

[30] Stewart, Larry, ‘A Meaning for Machines: Modernity, Utility, and the Eighteenth-Century British Public,’ The Journal of Modern History 70 (2), 1998, pp. 259-94, p. 294.

[31] This charmed state, if it ever existed, did not remain as instrument makers for example became increasingly excluded from the scientific community in the 1820s and the internal power relations of large engineering concerns developed. See W.T Ginn, ‘Philosophers and Artisans: The Relationship between Men of Science and Instrument Makers in London 1820-1860,’ Unpublished PhD dissertation, University of Kent, Canterbury UK, 1991.

[32] G.Wilson, The Industrial Museum of Scotland in Its Relation to Commercial Enterprise, A Lecture Delivered at the Request of the Company of Merchants of the City of Edinburgh, 4 December 1857, by George Wilson, Regius professor in the University of Edinburgh and Director of the Industrial Museum of Scotland, Edinburgh, R & R. Clark, 1858, p. 9.

[33] Wilson, ibid., p. 43.

[34] See Julie L. Mellby, Princeton University Library Graphic arts blog entry 3 February 2013, ‘Gavard, diagraphe et pantographe’.

[35] Martin Kemp, The Science of Art, New Haven and London: Yale University Library, p. 188.

[36] David Napier, ‘Universal Perspectigraph,’ Society of Arts, Transactions 1819.

[37] As in Charles Pasley’s Lancastrian pedagogical methods instituted in the Engineer Department of the British Army in the 1820s; Pasley, C.W., A Complete Course of Practical Geometry, London: T. Egerton, Military Library, 1822.

[38] Staubermann, Klaus, ‘What Machine Tools Can Tell Us about Historic Skills and Knowledge,’ International Journal for the History of Engineering and Technology 80.1 (2010): 119-132.